TPO Roofing Membrane:

- TPO, short for thermoplastic polyolefin, is a single-ply thermoplastic roofing membrane that offers good overall performance and great energy efficiency for the money.

- Reliable durability – TPO membranes resist mold growth, impacts, and punctures. It is made to be flexible to allow for a building’s thermal expansion and contraction which makes it ideal for buildings that need to house heat producing industrial equipment or refrigerated storage.

- Simple installation – Single-ply roofing membranes can be manufactured in lightweight larger sheets that are easier to install with fewer seams, translating to less time required for installation.

- Exceptional energy-efficiency – TPO has a reflective white surface which exceeds the EPA’s Energy Star requirements. This is attractive to businesses and homeowners that are looking to reduce energy costs while keeping the building comfortable. (White Color ONLY)

- Environmental sustainability – Going green? TPO roofs are an ideal option. They reduce the amount of energy waste from your HVAC system through their solar reflective properties. It’s also a completely recyclable roofing option.

- Thermoplastic membranes are fabricated from polymers which soften when heated and harden when cooled. The membranes can be welded together with heat or solvents, and when welded, develop a bond strength which equals or surpasses the strength of the base material. Heat Weldable membranes.

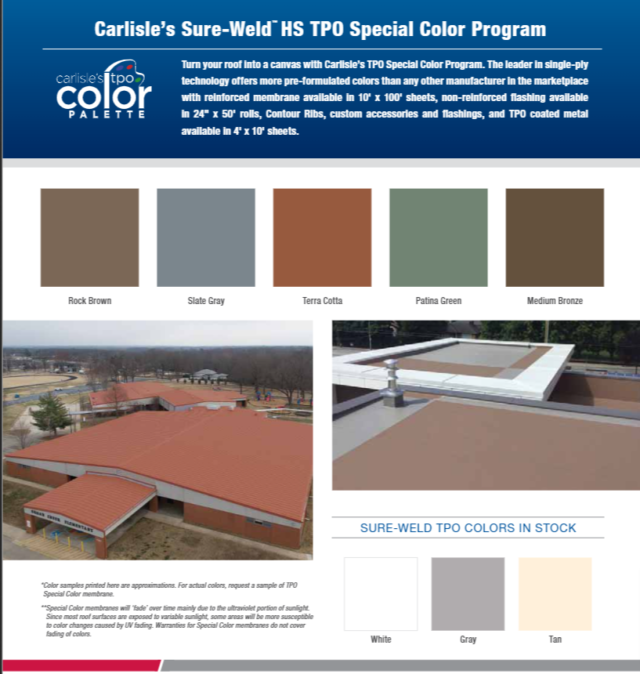

- TPO membranes are a newer product that made their initial appearance in the 1990s. TPO also comes in various color options vs the standard dark or black membranes. The default TPO color is white.

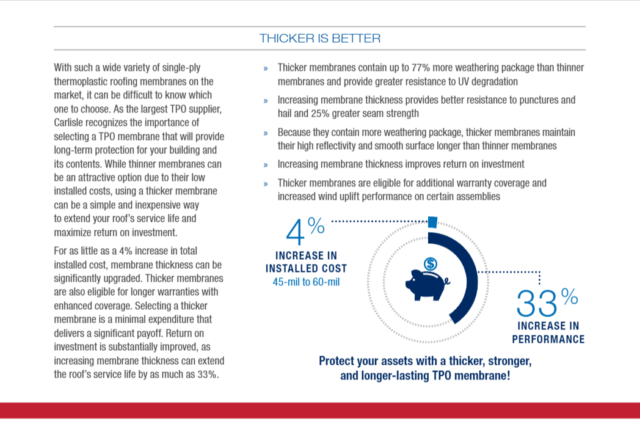

- TPO is available in multiple thicknesses which makes them more versatile than most flat roof systems.

- Thickness Options (in mils): 40 -100 mil.

- 60-mil is the most commonly used residential option

- TPO membrane chemically bonds rubber, ethylene, and propylene, as well as numerous filler materials. In that sense, it’s somewhat closer to EPDM rubber than PVC, although, unlike EPDM, TPO membrane seams are hot-air welded (not glued at the seams).

- Similar to PVC, insulation boards are first fastened to the roof substrate. TPO also comes in rolls and can be mechanically fastened to the insulation boards or installed with the self-adhesive (fully-adhered).

- Expected Life-Span – 15-20 years

Considering TPO roofing?

If you are searching for a cost-effective roofing option that fits your needs, a TPO roof from St Joseph’s Roofing could function as the perfect option. TPO roofs are durable and resistant to debris build-up, bacteria, and dirt leaving your roof with a cleaner appearance and sustainable infrastructure. The flexibility of our TPO roofs makes it less susceptible to tears and other impact damage. Our goal is to deliver a solution that meets your needs without disrupting the harmony of your day-to-day life or workflow in your business.

At St Joseph’s Roofing, our TPO roofs are built with high-quality, durable materials that are ideally-suited to keep your home safe. Our roofing contractors specialize in offering exceptional customer service, including seamless installation, efficient maintenance, and comprehensive repairs for any roofing project. High-quality roofing doesn’t have to be a pipe dream—with TPO, we make it a reality. Reach out to our team today and find out how we can upgrade your roof.

TPO IMAGES - COMMERCIAL

TPO IMAGES - RESIDENTIAL

COMMON METHODS OF INSTALLATION

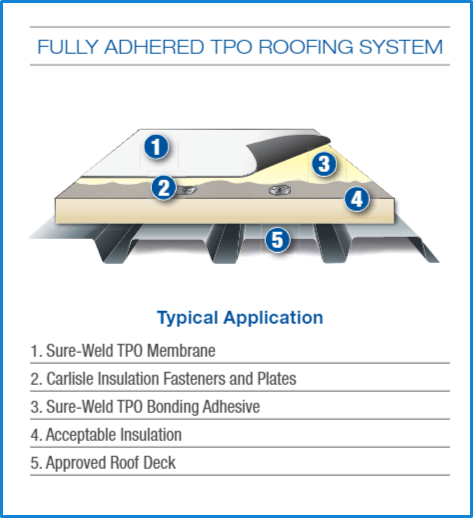

Fully Adhered

Fully adhered membranes have a higher  cost, but are less prone to damage and leaks. Generally, the insulation or roofing board is mechanically fastened to the structure and then the roof membrane is adhered to create a full assembly that resists uplift. Fully adhered membranes can also be installed directly to concrete or wood substrates.

cost, but are less prone to damage and leaks. Generally, the insulation or roofing board is mechanically fastened to the structure and then the roof membrane is adhered to create a full assembly that resists uplift. Fully adhered membranes can also be installed directly to concrete or wood substrates.

Mechanical fasteners are often used with fully adhered membranes to ensure added reinforcement at transitions, terminations, and parapet conditions.

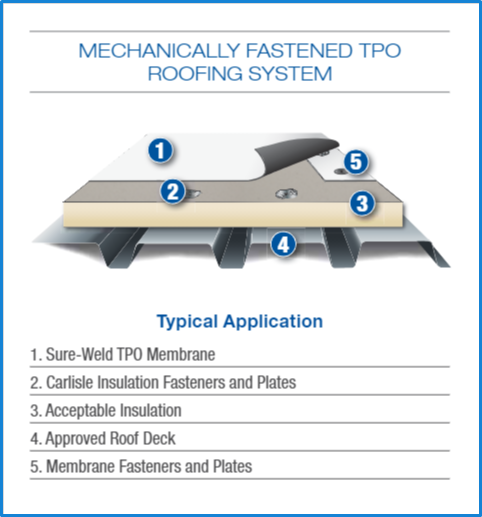

Mechanically Attached

Mechanically fastened membranes are directly anchored to the substrate and provide good resistance to uplift forces, but are more prone to leaks. In most cases, a disc or batten bar fastener penetrates the membrane and is then covered with a welded patch that creates a full seal. There are also non-penetrating fasteners for certain types of membranes. Installers must be very careful that all penetrations are well sealed.

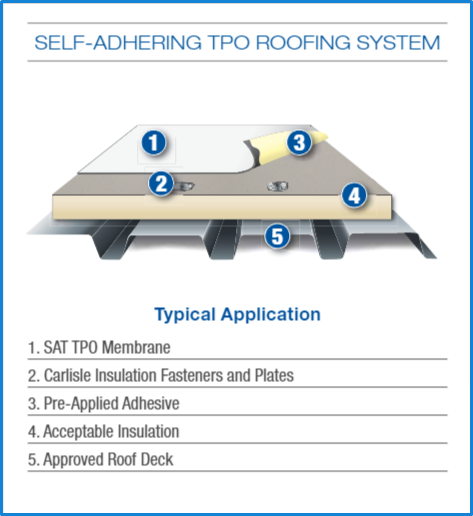

Self-Adhered

A self-adhering roofing system consists of a nailable base or self-adhering ply base with a top surface designed to accept a self-adhering roofing membrane, a self-adhering mid ply and a self-adhering cap sheet. Self-adhering roofing systems offer several advantages for contractors: no torches, no hot asphalt, no fumes and no mess — all of which means application is much cleaner and faster.